Research

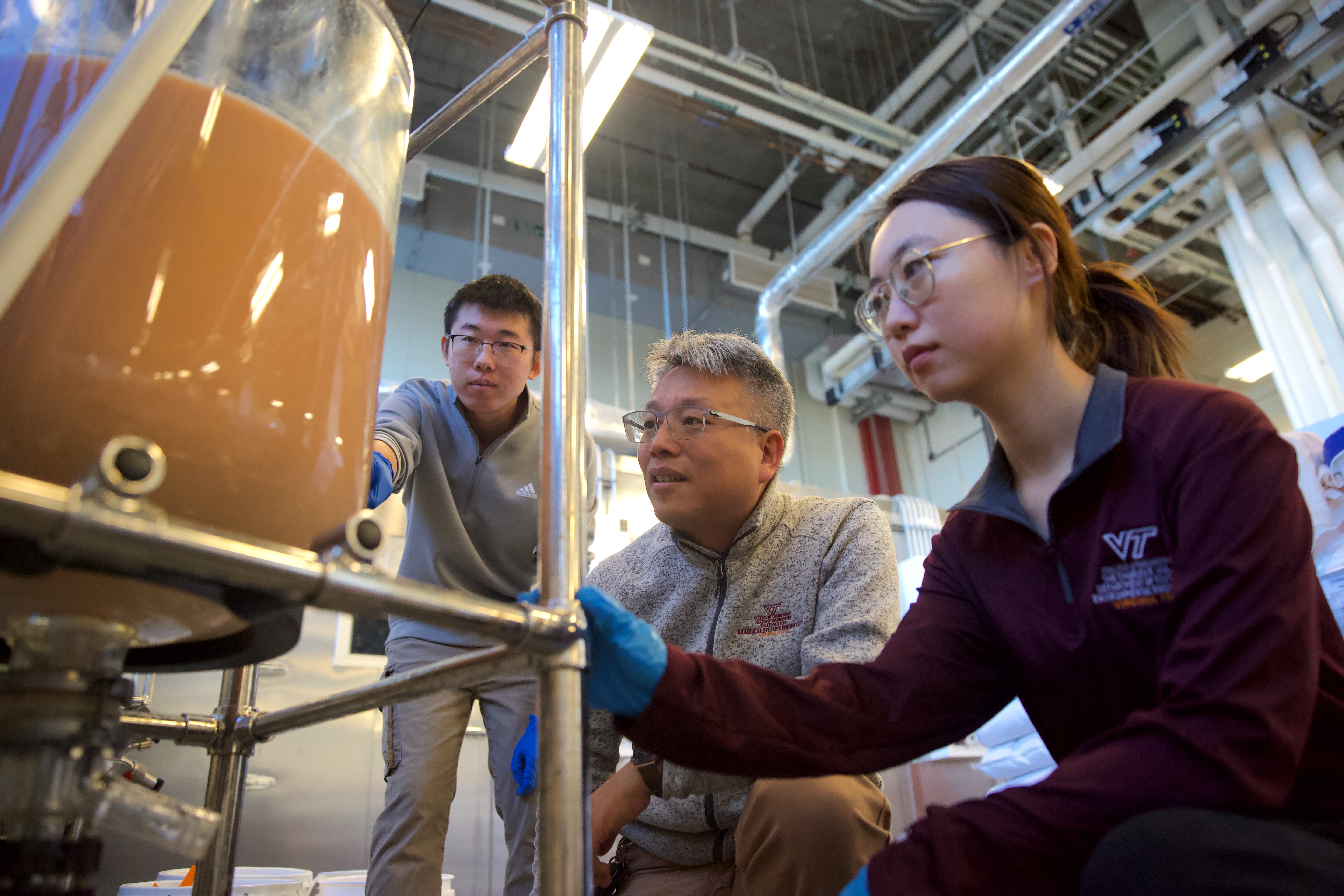

Bioplastic production from food waste

Most commercial plastics used nowadays are petroleum-based. More than 67% of end-of-life plastics end up in landfills, and another eight million tons annually make their way into the ocean where they are not degradable and only accumulate. In the past three pandemic years, the global consumption of the single-use plastics for keeping hygiene have created significant societal and environmental concerns. There is an urgent need for developing biodegradable plastics from renewable sources. The use of plastics is closely linked to another important environmental issue, namely food waste. Nearly 40% of food produced is dumped in landfills, accounting for the single largest component of U.S. municipal solid waste, resulting in not only greenhouse gas emissions but also an annual cost of $165 billion in economic loss including the food itself and associated water, energy, and chemicals spent in the food supply chain. The conversion of food waste to “value-added bioplastic materials” that can be biodegraded in environment may offer a unique solution to both environmental issues.

Dr. Wang’s study targets the production of naturally occurring biodegradable polyesters synthesized by many microbes as the basic materials for producing bioplastics capable of being degraded in various environmental conditions including ocean conditions. A three-pronged modular bioprocessing system is experimented in his lab to enable a variety of microbial cultures to convert a wide spectrum of food wastes into bioplastics with productivity high enough to outcompete other bioplastic production technologies. The overall goal of Dr. Wang’s research is to develop and demonstrate a pilot-scale modular bioprocessing system to produce bioplastics from food wastes with cost competency. This circular diversion of food waste for bio-based plastic production holds promise to reduce landfill quantity and waste management cost, offset petroleum-based plastic production and pollution, minimize greenhouse gas emission, and bring environmental justice to disadvantaged communities. An interdisciplinary team is assembled from three land-grant universities and a private enterprise to provide all the technological and marketing components required for the success of this advanced modular system. An industrial advisory board consisting of stakeholders and beneficiaries of the technology is formed to ensure delivery of the technology with good application relevance.

Bioprocess intensification

Bioprocess intensification is the process of making biological or chemical treatments more efficient and productive. In simple terms, it involves finding ways to get more out of processes like wastewater treatment or biogas production, while using less energy, resources, and space. This can be done by improving the design of equipment, speeding up reactions, or combining different methods to make the entire process work better and faster. The goal is to treat waste more effectively, recover valuable products like energy or nutrients, and reduce environmental impacts.

Dr. Zhiwu Wang’s bioprocess intensification research focuses on improving the efficiency and sustainability of wastewater and waste treatment systems through innovative technologies. His work includes enhancing anaerobic digestion by using thermal hydrolysis to increase the breakdown of organic materials, leading to higher biogas production and better dewatering of sludge. Additionally, he explores the integration of various processes, such as aerobic granulation and the use of kenaf-based ballasting, to intensify biological treatment, improving pollutant removal and resource recovery. Overall, his research aims to make waste treatment processes more efficient, reducing environmental impacts while maximizing the recovery of valuable byproducts like energy and nutrients.

Low carbon nutrient removal

Dr. Zhiwu Wang’s research on low carbon nutrient removal focuses on using advanced biological processes, such as anaerobic ammonium oxidation (anammox) and genetically modified plants, for eliminating nutrients like nitrogen and phosphorus from wastewater while minimizing greenhouse gas emissions. This approach not only minimizes the carbon footprint of wastewater treatment but also improves the overall sustainability of nutrient removal processes, contributing to cleaner water systems and reduced environmental impact.

Emerging contaminant removal

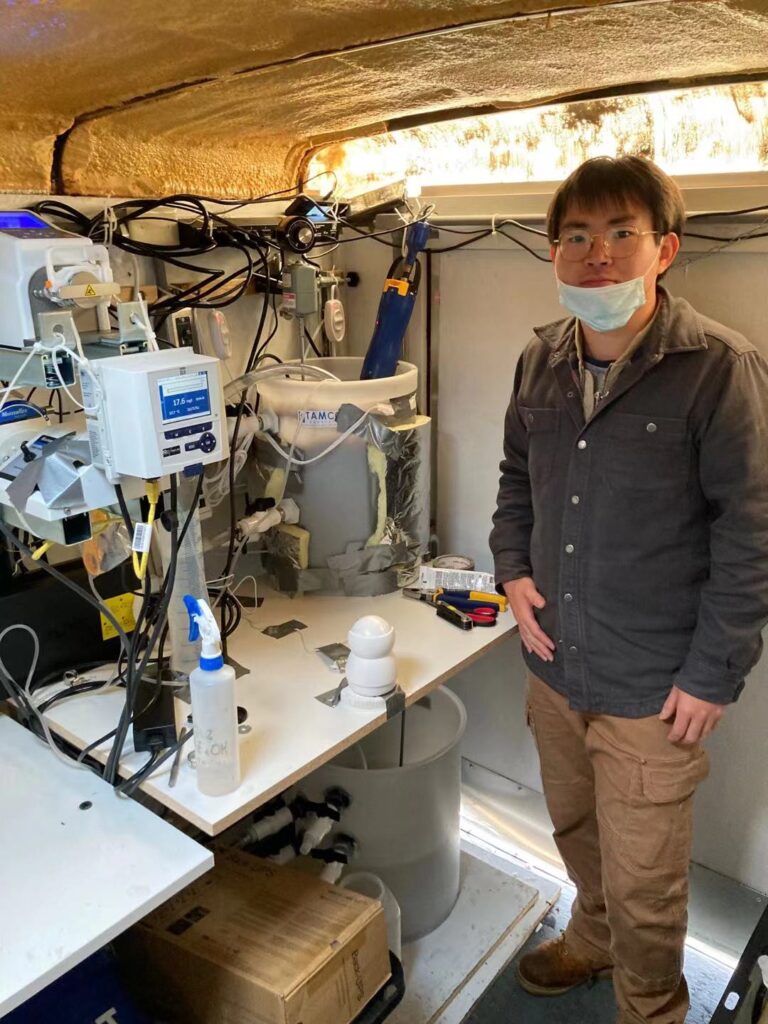

Dr. Wang’s research on emerging contaminants focuses on developing innovative methods to detect, remove, and destroy pollutants that are resistant to conventional wastewater treatment processes. A significant part of his work addresses the removal of per- and polyfluoroalkyl substances (PFAS), often called “forever chemicals,” which are persistent in the environment, as well as the recalcitrant dissolved organic nitrogen (rDON) formed from Maillard reaction during thermal hydrolysis of municipal sludge. His research includes exploring advanced oxidation, physicochemical adsorption, as well as advanced technologies like biocatalytic degradation and hyperspectral imaging for real-time detection of microplastics. By targeting these and other emerging contaminants, his work aims to improve water treatment processes, reduce environmental contamination, and mitigate the long-term health risks associated with these pollutants.

Solid waste anaerobic digestion

Dr. Wang’s anaerobic digestion research focuses on improving waste treatment and resource recovery by using innovative approaches, particularly in enhancing the efficiency of biogas production and nutrient recovery. His projects include treating agricultural waste, such as poultry litter, to produce biogas and recover valuable nutrients like struvite. Additionally, he investigates the use of thermal hydrolysis to enhance anaerobic digestion of municipal sludge, improving the breakdown of waste, dewatering efficiency, and overall biogas yield. These efforts aim to develop more sustainable and efficient methods for managing waste in both agricultural and municipal settings.